Gabbiani P60 (3300) - 10' Front Load, 2.36" Blade Proj., 15HP Main Motor, High Speed, Single Side Aligner, Pneumatic Blade Change

Gabbiani P80 (3300) - 10' Front Load, 3.15" Blade Proj., 15HP Main Motor, High Speed, Double Side Aligner, 2 Position Blade Height Control, Pneumatic Blade Change, Grooving

Gabbiani P80 (3800) - 12' Front Load, 3.15" Blade Proj., 15HP Main Motor, High Speed, Double Side Aligner, 2 Position Blade Height Control, Pneumatic Blade Change, Grooving

Selectable air blowing table: an essential tool.

The possibility to enable/disable the air blowing device on each table section via independent motors,ensuring optimal sliding of the panels only where it is neededand avoids accidental falling of cut panels temporarily stored on the tables.

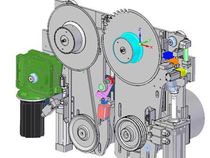

Saw carriage with independent raise of the blades.

Essential tool for machining post-formed panels in order to optimise cycle-time machine and enhance cut finish.

FLEXCUT unit: incomparable flexibility and productivity.

Increasing of productivity up to 30%andspace saving up to 20%owing to the simultaneous execution of both rip and cross cuts.

Floating clamps: the guarantee of the end result.

The special shape of the clamps allows safe grip of panels at the maximum speed and perfect parallelism even when panels are not perfectly planar.

| Cutting length | mm | 3300/3800/4300 | 3200/3800/4500 |

| Blade projection | mm | 60 | 80 |

| Saw carriage variable speed (option) | m/min | 6 - 60 (0 - 120) | |

| Pusher variable speed (option) | m/min | 0 - 60 (0 - 70) | |

| Main blade motor S6 - 40% (option) | kW | 7 (9) | 7 (9) (11) |

| Scoring unit blade motor 50 Hz (option) | kW | 1,5 | |

| Main blade / scorer speed 50 Hz | rpm | 4650/5850 | |

| Main blade / scorer blade diameter | mm | 300/200 | 340/200 |

| Number of clamps | std | 5 | |

Ideal solution for small-sized companies.

Single-blade beam saw controlled by PC/PLC control system, designed to cut solid wood panels or panel stacks and its products (chipboards, MDF panels, multilayer panels, plywood panels and fiber panels). The solution to integrate the beam saw inside a flexstore s or flexstore el storage.