• Touch-screen monitor for control of most saw functions, information, and diagnostics

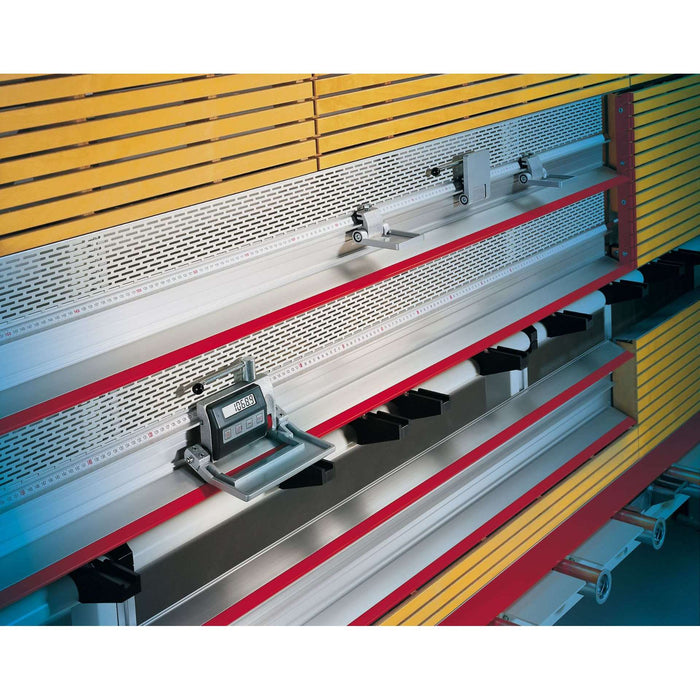

• Digital measuring X-axis stop (for vertical cuts) with fine adjustment, quick and easy referencing, push-button selection to reference from another cut station, and selectable display increments

• Y-axis digital measuring with fine adjustment on kerf compensation controlled at touch-screen

• Second measuring channel with three auxiliary stops for repeat cuts, plus “Compact-style” stop

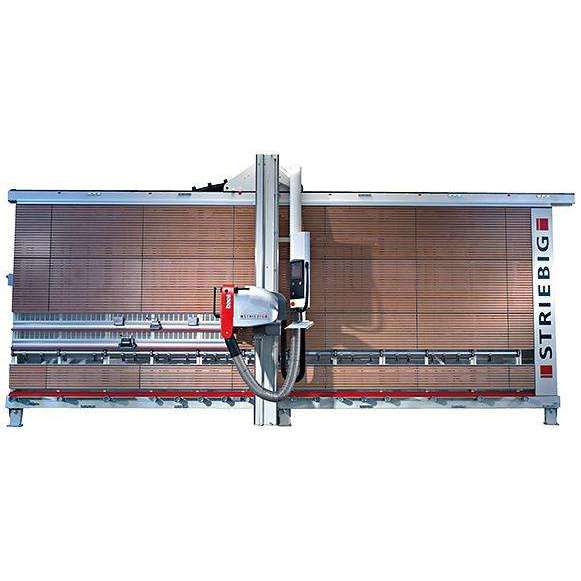

• Extremely stable, all welded steel frame suitable for free-standing or wall-mount installation

• Convenient, sturdy, two-section center shelf with moveable aluminum fingers allows for comfortable working of smaller parts and ability to stage material on one side of the saw

• Automatic recognition and locking of beam at vertical cut stations; unlock at the press of an icon

• Touch-screen control for rotating, plunging, and locking/unlocking of the saw head and beam

• Duplicate buttons conveniently located on front of the saw head for plunge, and scoring

• Automatic locking of the heavy-duty panel support rollers when cut cycle is started

• Automatic, mechanically shifting, full wood support grid- great for full support of thin, flimsy materials and an added level of dust control

• Laser light to help guide set-up of horizontal cut position

• TRK dust system exceeds European standards by 100%; note: requires a collection source

• Vertical cut stations 40 inches on center (1 meter spacing available for all-metric shops)

• USB port to enable uploading of Excel lists of part dimensions

• 7.5 hp, 220V, 3-phase motor with electric brake

• 300 mm (11-7/8”) HFG (hollow-face) carbide saw blade; ideal for melamine and veneers

• Document holder (removable) to keep cut lists in optimum viewing position near control panel

• Digital measuring X-axis stop (for vertical cuts) with fine adjustment, quick and easy referencing, push-button selection to reference from another cut station, and selectable display increments

• Y-axis digital measuring with fine adjustment on kerf compensation controlled at touch-screen

• Second measuring channel with three auxiliary stops for repeat cuts, plus “Compact-style” stop

• Extremely stable, all welded steel frame suitable for free-standing or wall-mount installation

• Convenient, sturdy, two-section center shelf with moveable aluminum fingers allows for comfortable working of smaller parts and ability to stage material on one side of the saw

• Automatic recognition and locking of beam at vertical cut stations; unlock at the press of an icon

• Touch-screen control for rotating, plunging, and locking/unlocking of the saw head and beam

• Duplicate buttons conveniently located on front of the saw head for plunge, and scoring

• Automatic locking of the heavy-duty panel support rollers when cut cycle is started

• Automatic, mechanically shifting, full wood support grid- great for full support of thin, flimsy materials and an added level of dust control

• Laser light to help guide set-up of horizontal cut position

• TRK dust system exceeds European standards by 100%; note: requires a collection source

• Vertical cut stations 40 inches on center (1 meter spacing available for all-metric shops)

• USB port to enable uploading of Excel lists of part dimensions

• 7.5 hp, 220V, 3-phase motor with electric brake

• 300 mm (11-7/8”) HFG (hollow-face) carbide saw blade; ideal for melamine and veneers

• Document holder (removable) to keep cut lists in optimum viewing position near control panel