SUPERAPID 401 Hotmelt Cleaner is perfect for cleaning your edgebander glue pot. It removes residue from interior of glue pot allowing you to run at the perfect temperature. It is the quick, easy, and economical way to clean and protect your edgebander equipment.

80% of all edgebander operating problems can be traced directly to the breakdown of glue from continuous heat exposure. Over time the inside of the gluepot becomes covered with a thick blackened coating that insulates fresh adhesive from the heating source. In addition, particles of the scorched coating will work free and clog up the glue roller. The results from not maintaining your glue pot are sporadic glue flow and defective bonds. Just add SupeRapid 401 cleaner to your gluepot, heat it up, activate the roller and forget about it for twenty minutes. After the pot cools, just wipe it clean.

**Not recommended for use in cartridge systems.

Documents: Cleaning Instructions, Safety Data Sheet

Container Size: 5 lbs. Box.

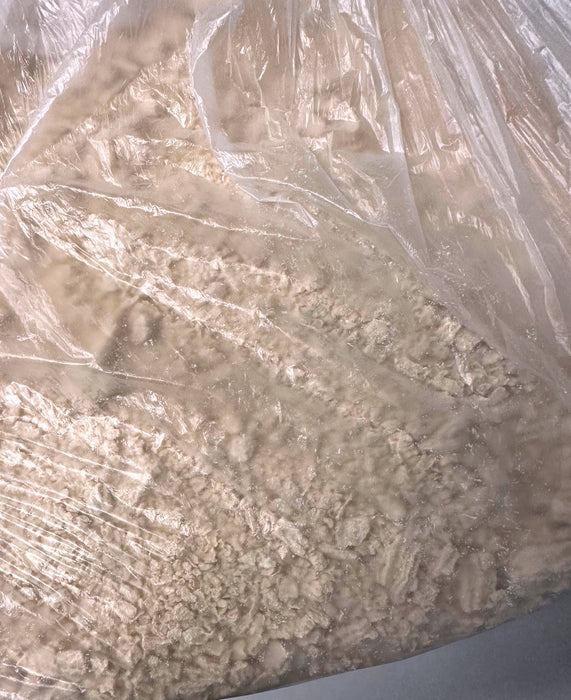

Appearance: Yellow-white, non-crystalline solid

Texture: Brittle Powder

Odor: Mild, sweet aromatic

Work practices: Keep away from sparks and open flame.

Handling & storage precautions: Store in a cool, dry area.

Cleaning Frequency: We recommend a cleaning every 3 months under normal working conditions (2-6 hours production per day). However, if glue is often overheated or left simmering (heat on - edgebander not in use) for several hours per day, then a more frequent cleaning will be necessary for best results.

A. For glue pots that are in great need of cleaning, but have never or seldom been cleaned previously:

1. Heat the machine to working temperature. Remove the maximum amount of glue from the pot with a scraper. For safety, be sure to wear gloves and goggles.

2. With the machine at LOW working temperature, add Superapid 401 to the glue pot and cover with the lid. LOW working temperature is normally 160o C = 320o F. Add approximately 2-1/2 lbs. of SuperRapid 401 during this step. DO NOT OVERHEAT!

3. Allow the cleaner (SuperRapid 401) to melt completely.

4. Activate the glue roller and allow the machine to cycle the cleaner for approximately 30-40 minutes with the lid on. (EP2, EP3, EP4. only)

5. Stop the machine and turn off the heat. Allow the glue system to cool for 15 - 20 minutes. Important: Do not wait until the unit is completely cold!

6. The sludge of cleaner mixed with old glue can now be removed easily from the glue pot. Simply use a scraper or spatula. Be careful not to touch the glue roller or any kind of thermostat with sharp, metallic objects during this process.

7. Replenish the glue pot with fresh hotmelt.

8. The next time the edgebander is used, run a scrap panel through several times for approximately 6 minutes to eliminate any cleaner that is trapped in the glue roller assembly. Use the same panel to avoid waste.

9. If the glue system is extremely dirty, then it may be worthwhile to repeat the process. This is especially true the first cleaning until a regular maintenance schedule is enacted.

B. For new or well-maintained systems:

1. Work normally with the machine until the glue level is very low.

2. With the machine at working temperature, stop the glue roller and add approximately 2-1/2 lbs. of Superapid 401 to the glue pot and close the lid.

3. Follow steps 3-8 under Section A. However, with a new or well-maintained glue pot, the cycle time in Step 4 may be reduced to 10-15 minutes.

CLEANING HOTMELT FROM SINGLE PARTS WITH SUPERAPID 401:

Use a heated pot with a lid (a crock pot will be fine) melting the Superapid 401 and submerging the parts in the solution. Let the parts soak 6-10 minutes, stir, and let soak 6-10 additional minutes.

NOTE: SuperRapid 401 will not completely remove carbonized char, but it will make it much easier to scrape away.

STORAGE OF SUPERAPID 401:

Superapid 401 should be stored in a cool, dry area. When using Superapid 401, make sure the area is well ventilated. Wear safety gloves and goggles when cleaning. Protect all exposed skin. When Superapid 401 is melted, it is very liquid. Be very careful not to splash it.

NOTE: When you unpack the hotmelt cleaner, the granules may stick together. This has no effect on the quality of the product. There is no need to take the time to break the granules apart. They will still melt down in the glue pot.