The surfacing-thicknessing planer powerful and user friendly, for D.I.Y. woodworkers and craftsmen workshops.

This 16” Jointer/Planer combo machine offers power and precision in a compact size for any shop. With long jointer tables, and sturdy fence, this machine is a quality product, made in Italy, for a value price. Find out why this machine may be perfect for you.

**The Minimax FS 41C does not come with the European Euroguard. This machine comes standard with the OSHA compliant American Spring Guard in the US**

XYLENT 16” CUTTERHEAD

Your Minimax FS 41C includes robust features. From the heavy duty 16” jointer to cast-iron tables and the breakthrough “XYLENT” cutterblock technology, this cutterhead eliminates the necessity of balancing single knives, significantly reduces the decibel level during operation and produces much smaller shavings. With the addition of the XYLENT cutterblock, you have long-lasting carbide knives that are designed to last and provide an excellent finish.

XYLENT MAITENANCE KIT

This kit was designed to help you get the most out of your new XYLENT cutterhead. With this kit you get one cleaning/degreasing liquid bottle for helping reduce resinous wood coatings. You will also get one dynamometric key set to 5.7 mm, two bit Torx T20, ten inserts of 15x15x2.5mm, five M6x15 T20 screws, one brass bristle brush to clean the spindle with the mounted inserts and one steel bristle brush to help clean out the insert housings. All in a beautiful and functional hardback case.

QUICK CHANGEROVER

Changing between jointer and planer is much quicker on this machine than other models. This is because there are two separate same-side dust collection outlets for the jointer and the planer. Also, it is not required to drop the planer table all the way down in order to change back to a jointer, saving you additional time. Lastly, when going back to using the planer function, you don’t have as much distance to travel to get to your planning thickness. The entire changeover process can be done in under a minute.

JOINTER FENCE

The Minimax FS 41C has a separate jointer fence which rides on a rail mounted to the jointer table. The fence has a cast-iron knuckle and is tiltable to 45°.

JOINTER/PLANER

The Minimax FS 41C has over a 70” Jointer bed, a 16” width cutterhead, comes with an USA OSHA approved American guard. The planer is able to process up to 9” thick material.

AMERICAN STANDARD GUARD

The Minimax FS 41C comes with an American standard guard. American safety standards state that when the guard is moved out of the way, and let go, it must automatically recover the cutterhead, which is why the American “pork chop” guard is standard. It is spring loaded to comply with American safety standards.

Optimal Planing

The planer unit in the standard version has a 72mm diameter cutter block. For an impeccable result, the pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined. The thicknesser infeed roller has helical toothing to guarantee strong, constant work piece feed. In contrast, the sandblasted steel outfeed roller maintains the perfect post-machining finish.

Absolute Rigidity

Very high rigidity of the surfacing fences made of extruded aluminum with 1670mm length.

“Xylent” Spiralknife Cutter Block with 3 Series of Knives

The 3 spiral knives give an exceptional finish. Reduced noise during machining provides a more comfortable working environment. It also improves the dust extraction due to the production of very small chips. Each cutter has 4 tips which can be rotated into the cutting position when worn. Therefore increasing the production life of the cutter block before knives require replacement.

STANDARD EQUIPMENT

- Precision-milled cast iron tables

- XYLENT Technology Silent Cutterhead with 66 knives

- XYLENT Maintenance kit with 10 additional knife inserts

- Side Mounted Jointer fence

- Jointer tables open away from the operator

- American-style jointer guard

- Tool set and operator’s manual

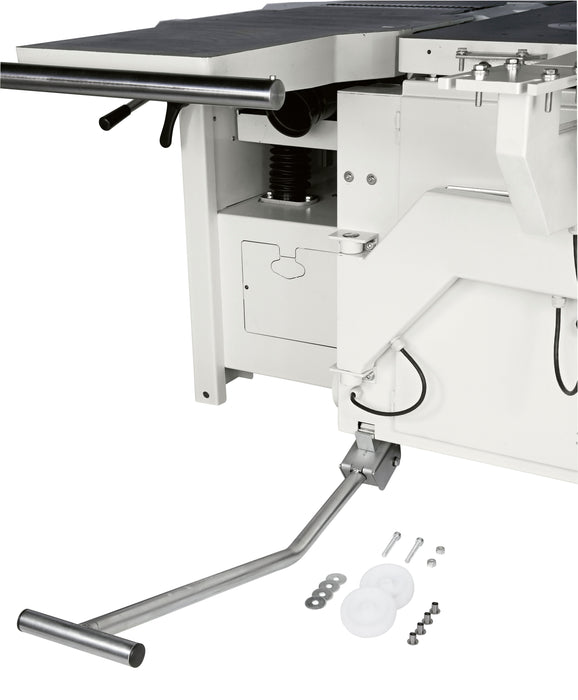

- Mobility Kit

- Wheels for machine movement

SCM MINIMAX FS 41C JOINTER-PLANER SHOWCASE VIDEO

SCM MINIMAX FS 30C JOINTER-PLANER VIDEO WITH SAM BLASCO

SCM MINIMAX FS 41ES JOINTER-PLANER COMBINATION VIDEO WITH SAM BLASCO