Models

ME 35ET

10" EYE-S touch screen control, Units: Dual pre-mill, End trim with RADIUS feature, Top/bottom trim, Profile scrape, Buffing

ME 35ETR

10" EYE-S touch screen control, Units: dual pre-mill, Combined End trim and Corner rounding, Top/bottom trim, Profile scrape, Buffing

The Minimax ME 35 is a Single or Three-phase automatic edge bander with great flexibility for both thin and thick edges, intended to bridge the gap between a traditional small to mid-sized edge bander for woodworkers; to the more robust equipment used in the Classical line of products. There is no competition in the U.S. market for such a small, versatile machine, with pre-mill or corner rounding units that are so economical! This machine is meant to be used with melamine edges, PVC and ABS up to 3mm.

Premiered at Xylexpo in Europe, the Minimax ME 35ETR won first place under the “tooling machine” category for its ability to combine the corner-rounding and trimming features into a single tool, compact-sized machine with a minimal footprint. This applied technology makes this edge banding machine a must-have product for small to medium sized facilities, the ideal one-stop machine for facing and trimming the front and rear ends of panels, while at the same time, rounding the front and back edges all at an affordable price for every shop.

AVAILABLE MODELS

ME 35ET: 1-phase edge bander with automatic strip magazine, rapid glue pot substitution and internal lighting. Comes with the following (3mm radius tools) units: Dual pre-mill, End trim with RADIUS feature, Top/bottom trim, Profile scrape, Glue scrape, Buffing.

ME 35ETR: 3-phase edge bander with rapid glue pot substitution and internal lightning. Comes with the following (3mm radius tools) units: Dual pre-mill, Combined end trim corner rounding, Top/bottom trim, Profile scrape, Glue scrape, Buffing.

**$3,200.00 Installation Required, Freight Included**

PLC CONTROLLER

The control system for the Minimax ME 35 is an intuitive and easy to use interface. Positioned near the tape roll holder and infeed side of the machine, this allows for you to easily access all of the main functions. The PLC unit guides the operator during maintenance, cleaning, diagnostic operations and more.

PANEL HEIGHT ADJUSTMENT

Manual adjustment of the presser, with numerical readout and automatic positioning of the upper operating units according to the panel height.

TRACK FEED MOVEMENT SYSTEM

The Minimax ME 35 uses a track feed panel movement system that allows for precise and accurate positioning of the panel through each station. Designed for a perfect finish that eliminates transfer marks onto the work piece. 9 meter/min panel feed speed with track movement for increased productivity with dual presser wheels and panel roller support on the entire length of the machine. Monitoring of the panel position is done by an encoder for total work cycle control.

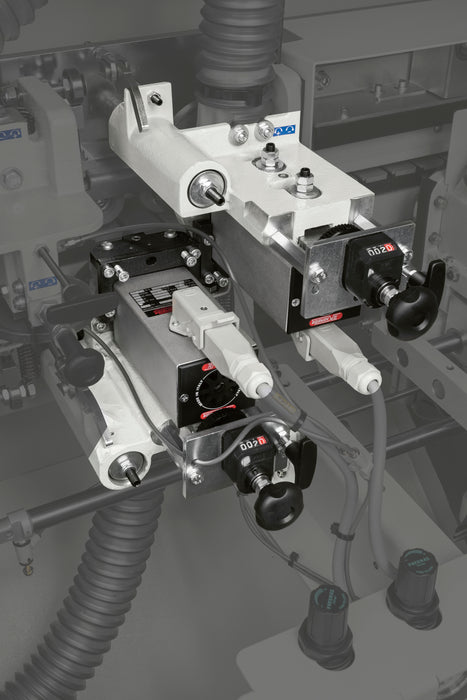

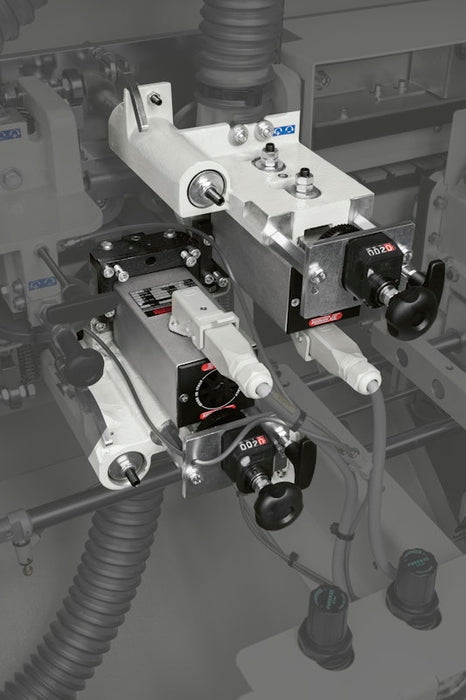

DIGITAL MECHANICAL READOUTS

Each station on the edge bander is easily adjustable and repeatable through the use of these digital mechanical readouts. Easily input the dimensions you are processing, and fine tune them simply. By taking note of the positions for the different panels you run, you can easily change the settings on the fly for any change in operation.

HIGH FREQUENCY MOTORS

Thanks to the high frequency motors of the end cutting unit and of the in-line top/bottom trimming units, the reliability of the Minimax ME 35 is unmatched. With the absence of belts or other conventional driving systems, we have engineered less vibration into the unit, increasing reliability and precision over the life of your machine.

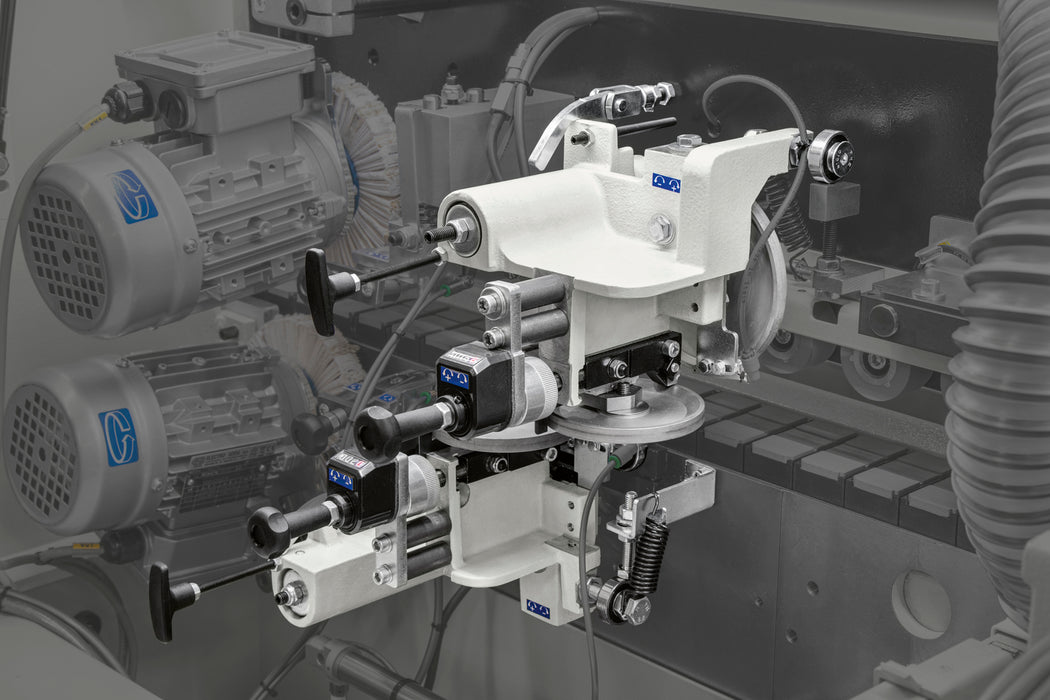

PRE-MILLING UNIT

The Minimax ME 35 Pre-mill unit is complete with two diamond cutters that are 80mm in diameter. This allows for a clean edge and a good lineal finish during the pre-mill process. Pre-milling comes with an independent exhaust and air blower for cleaning of the panel during this station. Vertical adjustment of pre-milling unit allows for even tool wear. Four manual shims of varying thicknesses (0.5 to 1 to 1.5 and 2mm) come with your ME 35ETR for setting stock removal thickness.

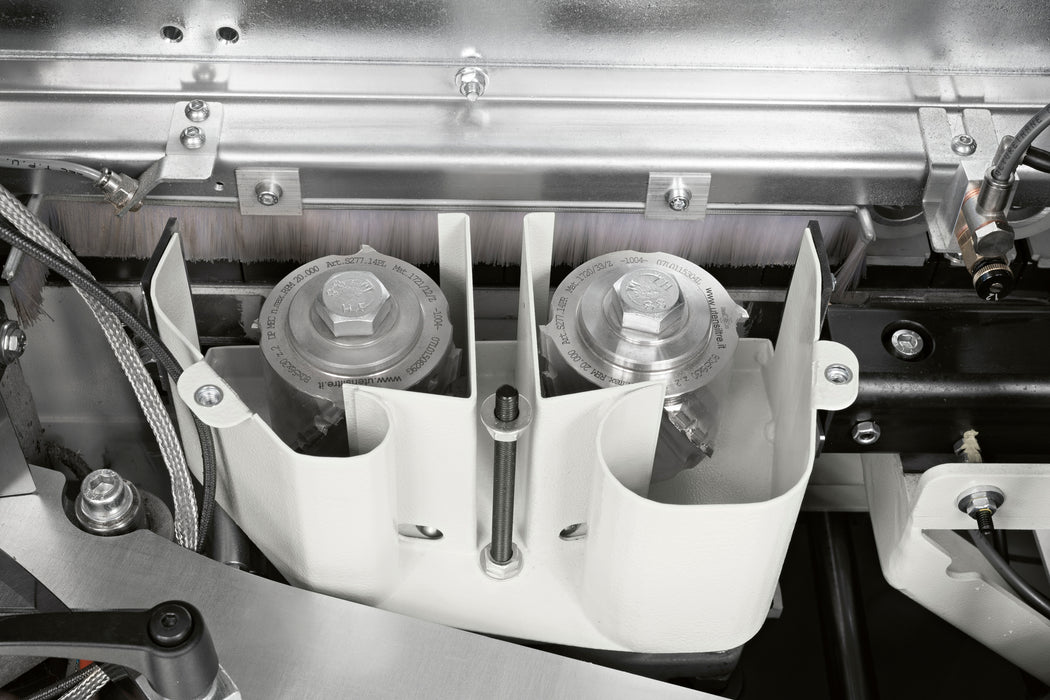

GLUE POT UNIT

The Minimax ME 35 edge bander features a glue pot with a quick heat-up system. This self-lubricating glue pot is Teflon coated to allow for easy clean up and replacement. The system easily applies the glue to the panel with a vertical glue spreading roller, and the temperature is adjustable via the PLC control. Additionally, the unit also has a device to automatically recover unused glue, and automatic lowering of the glue pot temperature after temporary non-use of the machine.

GLUE POT RAPID SUBSTITUTION KIT

This feature allows you to easily remove and replace the glue pot tank in the machine. This machine does not come with a spare glue pot which can be purchased with the machine as an optional accessory upon request (code 58.05.15).

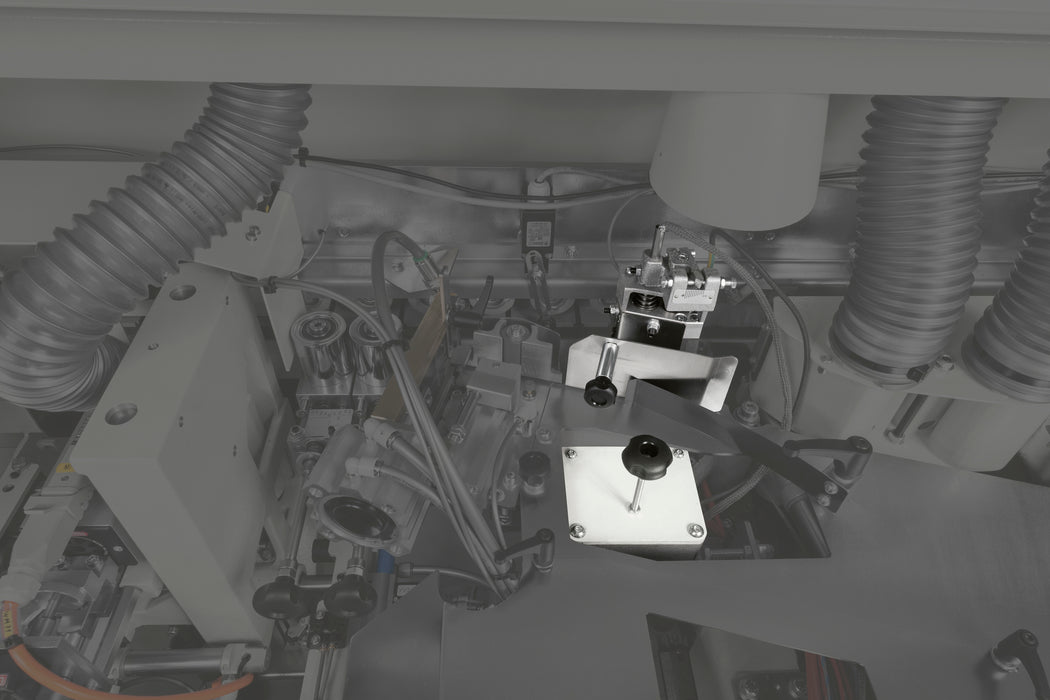

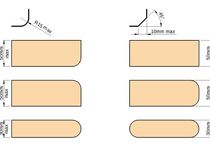

SPECIAL END-CUTTING UNIT WITH “RADIUS” FUNCTION (ME 35ET MODEL)

This station is installed in place of the standard end-cutting unit. During the process of cutting off the front and rear exceeding edges (except for solid wood strips), it rounds off the angles of the edge banded panel. This creates a beautiful radius edge. This function is directly controlled with the operator interface at the control panel. With its own independent high frequency motor running the blade at 12,000 rpm with an Ø 125mm Z12 blade, you can expect the finest finish of any edge bander in its class.

FULL CORNER ROUNDING END-TRIMMING UNIT (ME 35ETR CORNER ROUNDING MODEL)

During the process of removal of the front and rear exceeding edge; this two stage unit trims and rounds the edge in a single pass at the end of the panel. Driven directly from the control panel it is possible to work with only the end cutting function for thin tape and 3mm thick banding. This is the first unit in its class to have this advanced engineering, this small of a footprint and overall capabilities at a price point that allows the small to medium-sized shop to compete.

TOP/BOTTOM TRIMMING UNIT

The Minimax ME 35 is equipped with high frequency motors, horizontal and vertical copy wheels for accurate positioning of tools with reference to the cutting point. This unit is provided with 55.3mm diameter, combined cutters: the radius part of the cutter is used to trim 3mm radius edges and chamfered thin edges. The edge thickness is shown by two numeric readouts. The unit is equipped with independent exhaust systems.

EDGE SCRAPING UNIT

High finishing quality of material edges thanks to the radius knives that help ensure the elimination of any marks left from the trimming unit tools, all equipped with front and vertical copy wheels, and a user-friendly device for exclusion of the unit when it is not in use.

GLUE SCRAPING UNIT

Ideal for removing all excess glue squeeze-out on the top and bottom surfaces of the panel. Engineered with a high-polish finish, the adjustable copy shoes are designed to help prevent scratching on delicate materials.

BUFFING/BRUSHING UNIT

The buffing station includes two independent motors running at 2,800 rpm for edge cleaning and polishing. The unit is tilted, and vertically adjustable to optimize the polishing and cleanliness of your finished panel.

ME 35ET MODEL

ME 35ET MACHINE CONFIGURATION

- PLC Control System

- Panel Edge Trimming Unit for straight or radius trimming on thick or thin PVC, ABS, Melamine, Laminate or Wood

- Gluing Unit with auto-sensory cooling to avoid burning of glue

- Glue spreading roller with electrical resistance inside provides a uniform glue spread at maximum working temperature

- End Cutting Unit with high frequency motor for best finishing

- Monitors Temperature on the roller

- End Trim Unit with front and vertical copying pads and high frequency motors to generate high cutter rotating speeds

- Cutters are designed for straight or radius trimming with numerical readout setup

- Radius Scrape for use on PVC/ABS edges with user-friendly exclusion of the device when not in use

- Glue Scraping unit for removal of excel glue on the panel edge/joint

- Brushing Unit for removal of excess glue on the panel edge/joint

- Brushing Unit tilted vertically adjustable motors

- Automatic loading device for edges in strips

ME 35ET STANDARD FEATURES

- Safety enclosure

- Internal lighting

- Control panel on machine infeed side

- Main frame made of bended and welded steel plates to ensure a high rigidity structure

- Top steel presser with two rows of rubber coated wheels mounted on bearings and enclosure that covers the wheels

- Manual adjustment of top beam with automatic positioning of the operating units according to selected panel thickness

- Numeric indicator of the selected panel thickness

- Feed track coated with high friction rubber fixed on a ¾ industrial chain. Two sliding pad guideways, one round and one flat, to ensure straightness of movement and resistance to side loads. Manual track lubrication.

- Panel support roller which can be extended on the entire length of the machine

- Specific exhaust outlets for glue pot, pre-milling unit, and trimming units

- PLC and 4” graphic display with large and luminous characters

- Selection of working language

- Keyboard with “soft touch” pushbuttons and led light

- Adjustment and indication of the glue pot temperature encoder positioned on the panel feed track pinion

- Padlockable main switch and overload protection

- Emergency pushbutton

ME 35ETR CORNER ROUNDING MODEL

ME 35ETR MACHINE CONFIGURATION

- Corner Rounding end cutting unit for cutting and rounding of the

panel. (not suitable for processing of wood edges)

- PLC control system

- Panel edge trimming unit for straight or radius trimming on thick or thin materials;

PVC, ABS, Melamine and Laminate.

- Kit for glue pot rapid substitution that allows for the glue pot tank to be easily removed and replaced.

(does not come with spare glue pot)

- Gluing unit with auto-sensory cooling to avoid burning of glue.

- Glue spreading roller with electrical resistance inside provides a uniform glue spread at maximum working temperature for the entire length of the roller.

- End cutting unit with high frequency motor for the highest-quality finish.

- Temperature monitoring of the roller.

- Top/Bottom trim unit with front and vertical copy shoes and high frequency motors for faster rotating speeds.

- Cutters are designed for straight or radius trimming with numerical readout setup.

- Radius edge scrape for use on PVC/ABS edges with manual exclusion of the device when not in use.

- Glue scraping unit for removal of excess glue on the panel edge/joint.

- Tilted, vertically adjustable brushing unit motors for the polishing and finishing on the panel edge and joints.

ME 35ETR STANDARD FEATURES

- Control panel and interface on machine infeed side

- Machine frame made of high rigidity ribbed steel to guarantee excellent support for the operating units

- Top thick steel pressure beam with rubber coated wheels

- Track feed system

- Manual adjustment of top beam (panel height) with positioning of the operating units according to the selected panel thickness

- Numeric indicator of the selected panel thickness

- Specific glue smoke exhaust outlet

- Panel support roller which can be extended along the entire length of the machine

- Safety enclosure hood

- Internal Lighting

- Electrical cabinet with new PLC and improved performance, 4-lines display, padlock capable main switch and overload protection push buttons