The RSP VSD series of PneuTech compressors are robust and reliable machines - designed to run efficiently for many years. They have many features that make them superior to comparable compressors.

Brochure for RSP VSD Series 40-450 HP

Electronic Controller – Electronic control cabinet gives you customizable control over your air compressor. Features a pressure scheduler, built-in sequencer, analog output, dual function e-stop, proportional integral control, and RS485 communication.

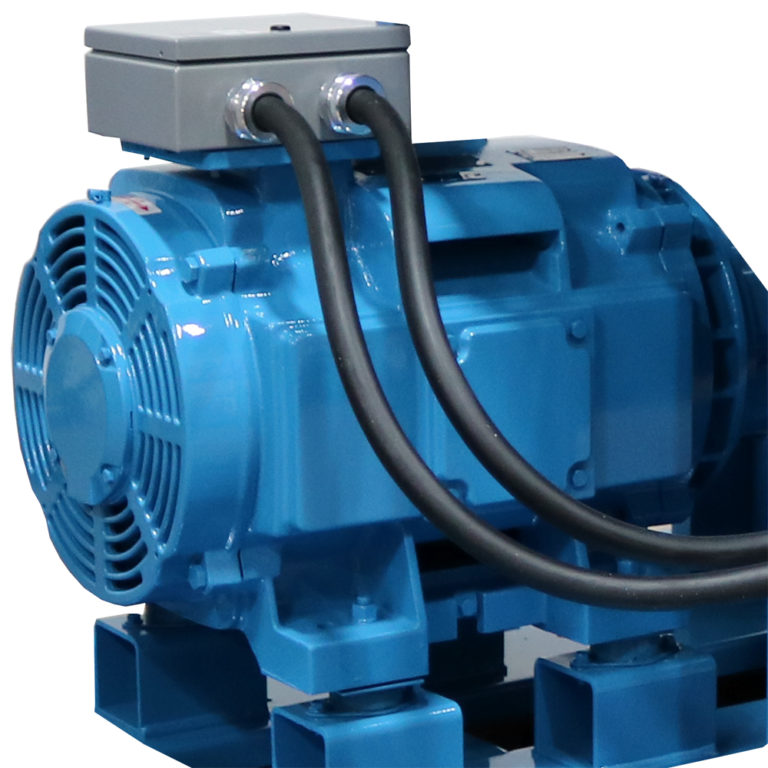

Direct Drive – Compressor is flange mounted to motor C-face for

positive alignment and direct drive. Yields lower maintenance and repair for your operation.

VSD Fan Motor – The fan motor ensures optimum airflow for proper temperature control. This brings you increased energy savings during low RPM compressor operation. Safety shutdown feature is enabled when cooling fan power is interrupted protecting you from catastrophic damage.

Variable Speed Drive – In contrast to the fixed speed air compressors, the VSD type regulates the speed of the motor depending on the amount of compressed air needed at a specific point in time. This makes the VSD feature very energy efficient.

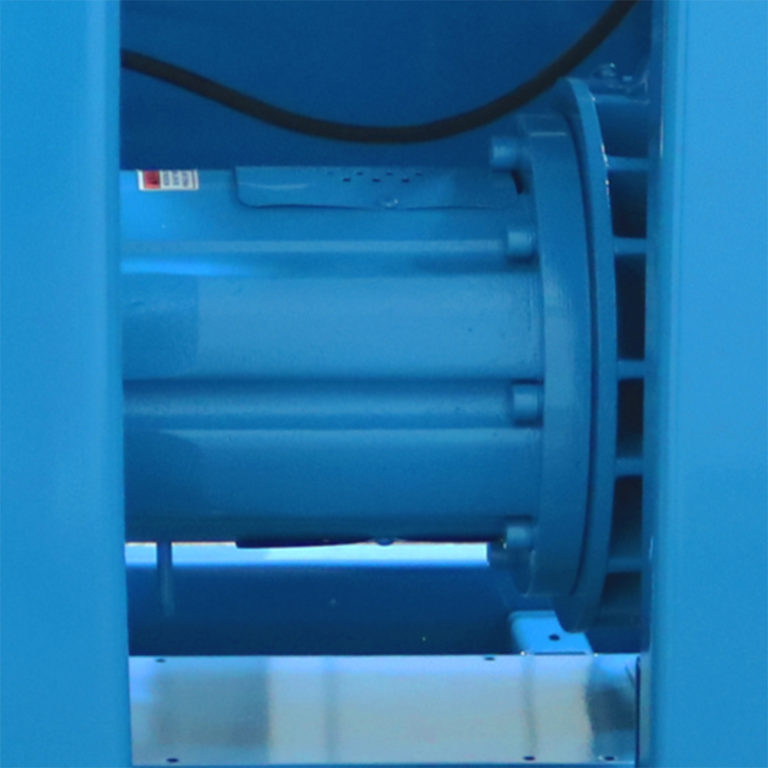

Main VSD Motor – The 208/230/460/575 three phase electric motor is a T-frame with a C-face flange. It is an induction type, open drip-proof design with squirrel cage cooling. TEFC motors are available on all models as an option.

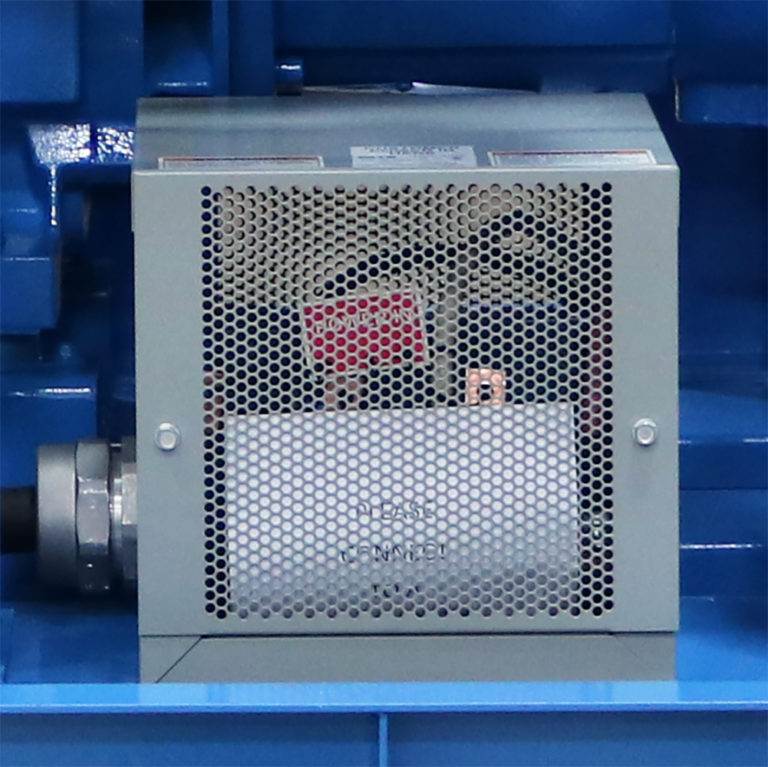

Line Reactor – The Line Reactor conditions incoming power as it evens out voltage. This standard feature offers you power factor correction, electrical noise suppression, and transient impulse protection.

Cooling System-Updraft Model – The RSP comes with a cooling system with an independent V1000 Variable Frequency Drive. It has a large side-by-side oil cooler and aftercooler for easy cleaning.

Oversized Air End – Oversized air end allows for low RPM leading to an extended lifetime for the unit. It also reduces noise in your operation.

Optional Additions:

- Power Outage Auto Restart

- Gauge Panel for Analog Verification

- NEMA 4 Electrics

- Enclosure Panels