11 Hp Manual and Electronic Spindle Moulder with Fixed Spindle

A must for the serious woodworker, the Class TF 130 is the SCM shaper that combines quality and value for your investment. It has a very robust structure and all the controls can be accessed on the front of the machine for easy use. A mechanical digital readout ensures the precision of the spindle adjustment.

**Does not come with the cast-iron table extensions shown in the product photo

Monoblock Base

Monoblock technology is used in the design and fabrication of this base. The solid, welded base undergoes a treatment call normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

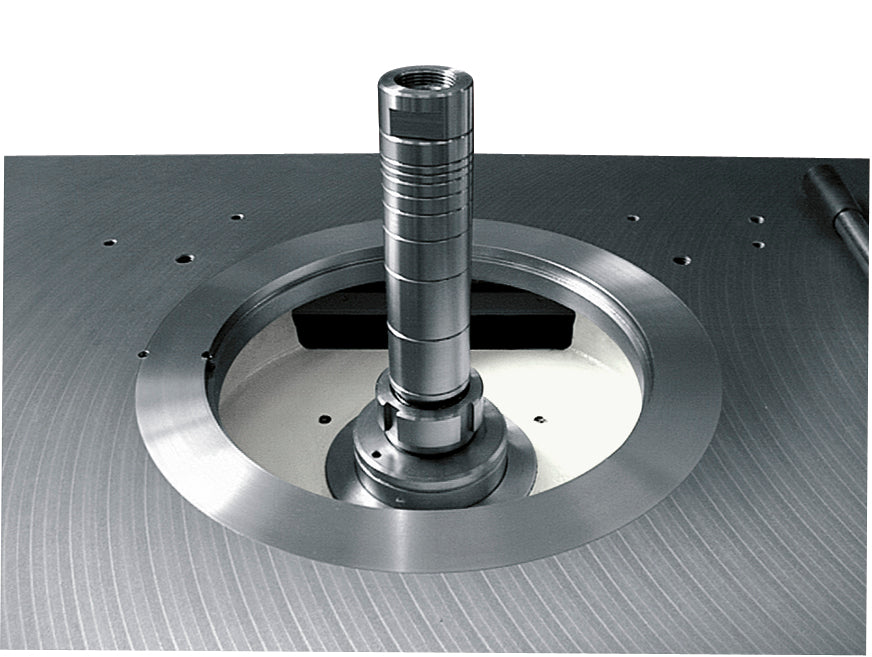

Large Spindle Assembly

One thing that can degrade the quality of finish from a shaper is the vibration transmitted from the spindle to the cutter. Minimizing vibration is even more critical when cutting tall profiles or using stacked tooling. SCM ensures maximum quality in its shapers by using very large spindle assemblies whereby the increased mass of the spindle absorbs vibrations and eliminates whipping action at the top of the spindle. All SCM shaper spindles are completely assembled and high speed balanced as one complete unit which further ensures vibration free performance.

Greater Tooling Flexibility

The Class TF 130 shaper includes a healthy 5.5 inch tool capacity under the nut. Coupled with the digital indicator for the spindle height, this makes the SCMI shapers perfect for the use of stacked tooling. For example, many woodworkers use a tooling package consisting of three cutters for making cabinet doors. The stile, rail, and panel cutters are all mounted on the same spindle. By raising or lowering the spindle, it is possible to perform all three operations without changing the cutter or the spindle. The five speed spindle further increases tooling flexibility.

MK 5 Removable Tapered Spindles

A standard feature on the Class TF 130 is the MK 5 interchangeable tapered spindle. This feature allows the use of different spindles for various tooling with different spindle diameters. An upgrade to a larger shaper does not mean that all tooling needs to be replaced. Special tools can continue to be used simply by changing out to a different spindle. A 1 1/4 inch spindle comes standard.

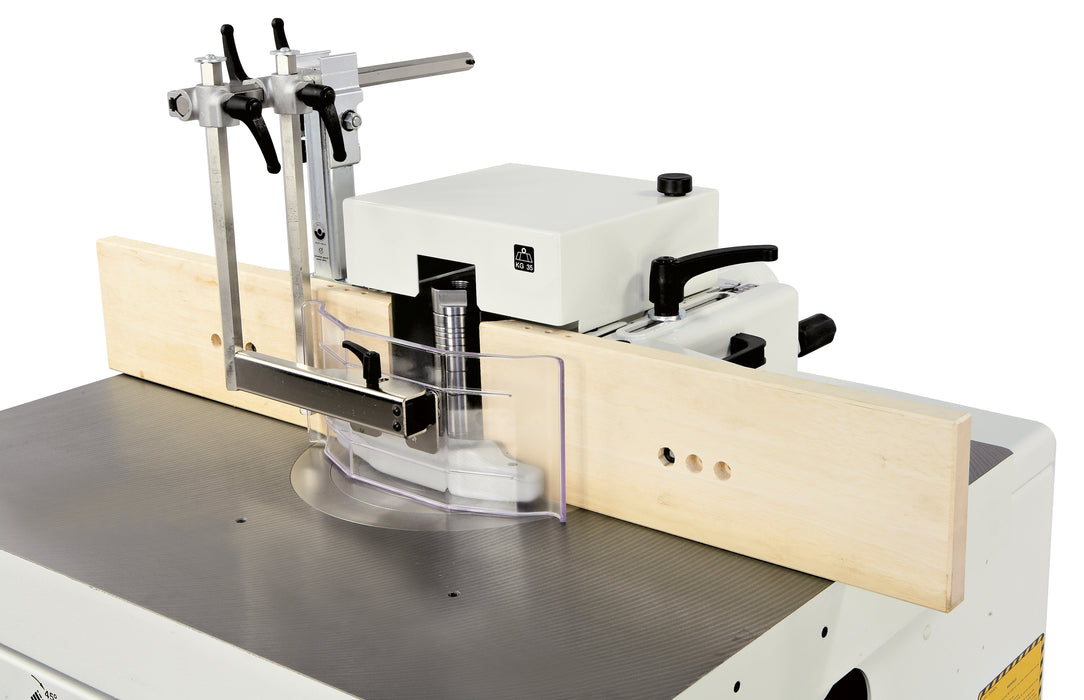

Mechanical Hood with Three Controlled Axis

The Class TF 130 comes standard with a large shaper hood with memory pins. If removed, the hood will go right back into the same position, so it is accurate and repeatable. The fences are adjusted by means of a mechanical hand crank that features a digital (mechanical) readout of the fence positioning. This convenient feature makes it simple to set up the hood for a number of different profiles and operations.

Set up precision and reliability. The operator easily adjusts every movement thanks to the handwheel with mechanical readout positioned on the machine front.

Very reduced machine set up time with the version with powered lifting of the spindle with controls and position digital readout positioned on the machine front.

Technical Data

Motor Horsepower: 11 HP

Table Dimensions: 48" x 29" (1200mm x 730mm)

Table Height: 36.2" (920mm)

Working Height of Spindle (under the nut): 5.5" (140mm)

No. 5 Morse taper Spindle Mount

Max. Tool Diameter: 9.8" (250mm)

Max. Insert Opening: 12.6" (320mm)

Spindle Speeds (rpm): 3,000 / 4,500 / 6,000 / 8,000 / 10,000

Dust Outlet on Fence and Rear Base: 4.72" (120mm) each

Overall Dimensions: 47" x 39.1" x 40.7"

Net Weight: 1,100 lbs.

Electrical Requirements: 3-phase, 230V

Dust Extraction: (2) 680 CFM