Installation - $4,500

General Features

DMC SD 70 RCS 135 SW & VN - TWO HEAD WIDE BELT SANDER

- Two Grooved rubber coated pressing rollers before and after working unit

- 3HP variable speed feed motor 3.5-18 m/min (12-60 FPM)

- Y-Delta two-stage reduced voltage starter on main motor

- Automatic Electronic Table Positioning Device

- In-feed / Out-feed extended tables for easier part feeding

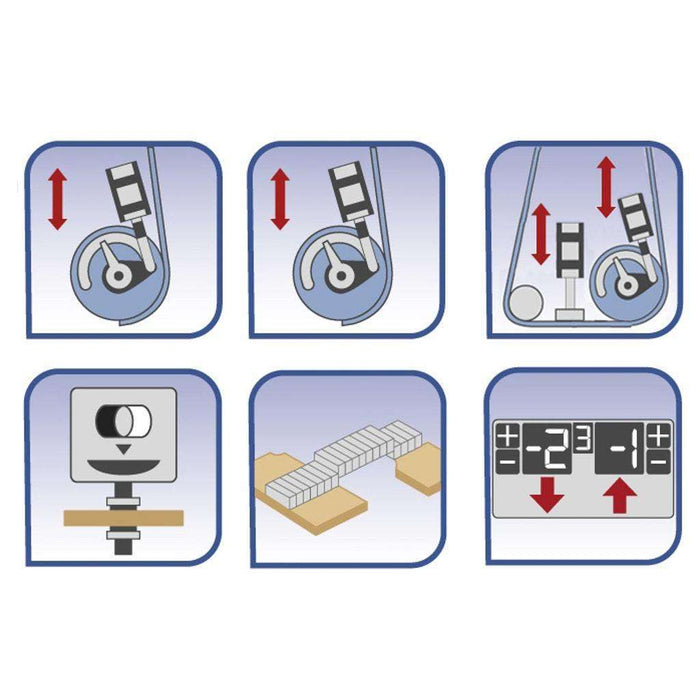

- Pneumatic On/Off selector of both rollers and pad

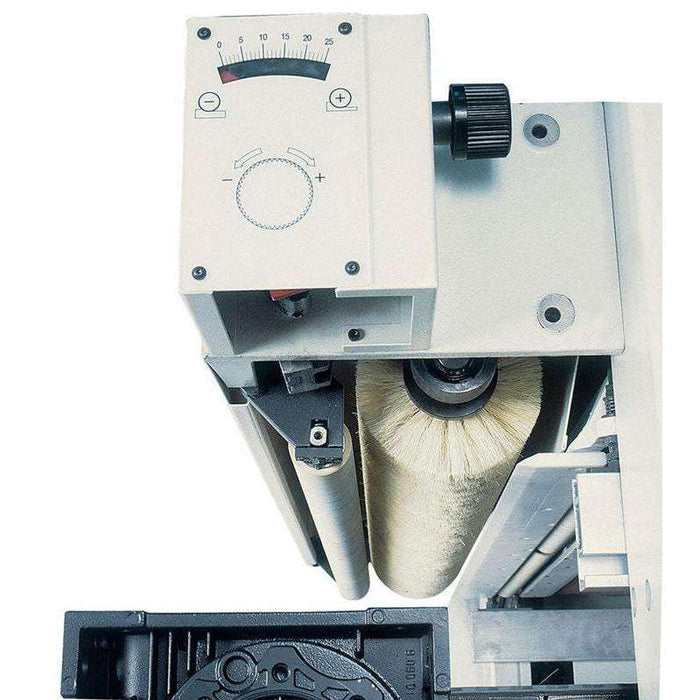

- Adjustable sanding drum and pad position for micro precision adjustment

- Electronic digital thickness readout of work table position

- Powered table lifting by means of four heavy duty motor and lifting columns double fastened at both top and bottom of the lifting columns to provide exceptional table stability

- Electronic tracking of abrasive belt

- Pneumatic belt tensioning with center fulcrum to compensate for tapering of abrasive belt

- Front and rear emergency stop button

- Amperage meter for main motors allows maximum utilization of available horsepower

- Main disconnect switch with the ability to be locked out by padlock

- In feed flexible steel hold down, and anti-kickback plate

- 50 shore, negative profile (waffle style) rubber feed mat

- LOGIC TS Electronic Touch Screen Programmer for timing/anti-dubbing of the pad

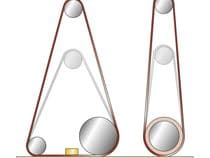

Long belts: 2,620mm length for greater finishing and productivity

Better cooling of the abrasive grit due to the greater development of the belts that reduces the adherence of processed dust. An extended belt length lasts longer, requires fewer replacements and consequently less downtime.

Automatic feed belt tensioning and centering: For an easy operation

An electro-pneumatic system keeps the feed belt on track, perfectly centered and tensioned at all times. The system is automatic and no operator intervention is required.

Belt oscillation controlled by an electronic photocell

This precision control system maximum uniformity in belt oscillation: this reduces the risk of belt breakage and improves finishing quality.

Technical Specifications

|

Model |

DMC SD 70 RCS 135 SW & VN |

|

Working Width |

1,350mm (53”) |

|

Number of Heads Available |

2 |

|

Feed Motor |

3 HP with inverter |

|

Feed Speed |

12 to 60 fpm |

|

Maximum Work piece Thickness |

170mm (6.69”) |

|

Minimum Work piece Length |

12.5 inches |

|

Abrasive Belt Size |

53” x 103” |

|

Compressed Air Requirements |

6 Bar (88 PSI) |

|

Dust Outlets |

2 outlets @ 195mm (7.75”) |

|

Exhaust Requirements |

3,544 CFM |

|

Power Requirements |

130 amps @ 230 Volts/3 phase |

Technical Specifications

| Working width | mm | 1.350 |

| Min. - max. working thickness (with mobile table) | mm | 4 - 170 |

| Min. - max. working thickness (with fixed table) | mm | 4 - 200 |

| Sanding belts width | mm | 1.370 |

| Sanding belts length | mm | 2.620 |

| Standard main motor power | kW (Hp) | 11 (15) |

| Motor power 1st group | kW (Hp) | 11 (15) |

| Motor power 2nd group | kW (Hp) | 11 (15) |

| Feed belt speed | m/min | 4,5/9 |

DMC SD 70 RCS 135 - 53" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE COMBINATION HEAD

DMC SD 70 RRCS 135 - 53" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE RUBBER DRUM ROLLER, ONE COMBINATION HEAD

SCM DMC SD 30, 60, 70, 90 | NEW HMI CONTROLLER VIDEO

SCM DMC SD 70 WIDE BELT SANDER BROCHURE