Automatic solution for the product packaging starting from a die-cutted cardboard foil (FEFCO 410 code) and the product manually positioned on the machine roller conveyor.

Thanks to the automatic dimension change setup, it is possible to manufacture packages with variable-sized boxes, placed in sequence on the roller conveyor. Such machines are suitable for manufacturers of flat-packed furniture.

HOT MELT is the technology for the closing of the boxes which ensures high quality packaging standards constant over time.

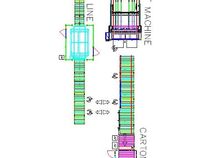

STAND-ALONE STATION OR TO BE INTEGRATED in complete packaging lines. It can be integrated into fully automatic production lines with 3D product dimensions reading, automatic cut of the tear-off and cardboard box wrapping and palletizing.

AUTOMATIC READING OF THE BOX DIMENSIONS, to adapt the process to the production requirements, starting from the large-scale to the small dimension batches down to the batch 1 manufacturing.

| pack c 90 | pack c 100 | ||

| Max. productivity (batch production*) * the value is calculated for boxes with L=1200 mm |

No. | 7 | 8 |

| Min. box length (external sizes) | mm/sec. | 400 | 400 |

| Max. box length (external sizes) | mm/sec. | 2900 | 2400 |

| Min. box height (external sizes) | mm | 40 | 25 |

| Max. box height (external sizes) | mm | 250 | 250 |

| Min. box depth | mm | 300 | 250 |

| Max. box depth | mm | 1050 | 1050 |

| Installed power (absorption) | A | 20 | 35 |

| Box weight | kg | 1600 | 3020 |