Class SI 400EP Blade Off Sliding Table Saw

220V, 3ph, 15 HP, 10.5' Slider, Tilting 16" Blade, 63" Rip Capacity, 10" EYE-S Controller (3NC Axis), 3 DRO Stops

Install of $3,200 required

Sliding Carriage

The anodized aluminum alloy carriage will never require adjustment and thanks to its structure with arch-ground hardened steel slideways (SCM exclusive and patented solution) it can bear loads four times higher.

Furthermore, the "arc" profile of the slideways ensures:

- No Play and no need for adjustments over time

- Higher loading capacity

- 10 years of SCM guarantee for the carriage sliding system

Optimizer/Sequencer App for Tablet: SCM Thundercut

Application to be downloaded from the App Store or Play Store on compatible tablets (mobile devices) equipped with iPadOS or Android operating systems.

It can be activated using the QR code supplied with the machine. The app allow for:

- Managing your machine stock and the material and panel magazine

- Create and modify projects, import projects from the main furniture design software ("cpout" file format), import cutting lists

- Optimize cutting lists, choosing from one or more proposals of the optimization software integrated into the App

- Set the machine correctly for each cut to be made, thanks to the simple and intuitive graphics of the 3D sequencer that guides the operator at each step

- Print labels with barcodes to identify the various parts, thanks to the Bluetooth connection with compatible label printers

"EYES-S Mini 10" Electronic Control Panel

Main Features:

- 10" touch screen display

- Direct control of the following working axes with manual, manual incremental, semi-automatic, automatic modes:

- Main blade lifting

- Saw blades unit tilting

- Parallel fence movement

- Operator's help functions for the carrying out of complex cutting

- Storage capacity up to 1000 programs

- Cut sequencer of the pre-loaded parametric working programs

- Environment for the creation and storage of the new sequenced working programs

- Automatic acquisition of the work quotas from the Thundercut

- USB port

- Pre-set for Network Connection

Overhead Mobile Control Panel

Motor Start/Stop Pushbuttons Integrated in the Sliding Carriage (for main and scoring blade)

Outfeed Table Extensions

Eccentric Clamp

Squaring Frame on Swinging Arm Support, with:

- Fast fence position for angular cuttings

- Idle roller to facilitate the panel loading/unloading

Telescopic Fence with 2 Flip-Over Stops and Imperial Rule Tilted Towards the Operator

**Digital readouts are not included as standard**

Programmed Parallel Fence

- Position readout on encoder

- Sliding on THK guide

- Adjustment by means of recirculating ball screws, 25 m/min max. speed

- Continuously adjustment by means of pushbuttons or automatic positioning

- Possibility of incremental positioning

- Automatic set up

- Total exclusion of fence under worktable

- 1600mm cutting width

Safety/Protections

- Emergency pushbuttons located on the front of the machine side

- Direct start main motor with pushbuttons

- Overload protection

- Overhead saw guard with incorporated dust extraction, 100mm outlet diameter

- Auxiliary low voltage circuit (110V)

- Automatic brake on main sawblade

- Main power switch can be locked in the off position with a padlock

- Blade access door with safety microswitch

- "CSA" rated electrical components, including cables

Included Tooling

- Trimming shoe, push stick and push handle

- Toolbox: wrenches, allen wrenches, user manual, spare parts catalog

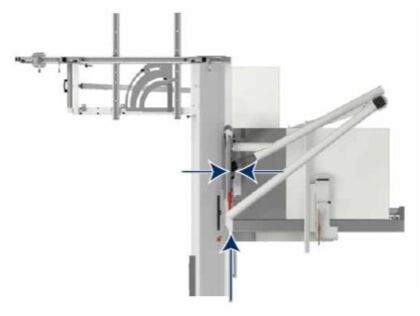

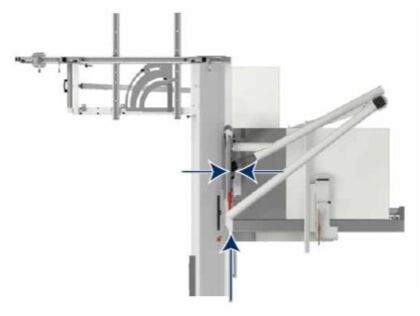

SMART SOLUTION

Due to the detection type, blade off activates regardless of the hand position and any other part of the human body inside the danger zone. The system operates despite of the personal protective equipment the operator wears; in fact, it also performs perfectly with any type of glove worn.

SAFETY AND ERGONOMICS

The new system for circular saws is the innovative technological solution designed by SCM to work in total safety.

The essential design ensures movement freedom related to overall dimensions and aesthetics impact.

REPEATABILITY AND RELIABILITY OVER TIME

The system provides the possibility of quick reset without compromising the machine quality and stability over time.

EXPANDED PROTECTION

The protection is guaranteed on the 3 areas next to the blade (work-piece infeed and side areas) to prevent any possible contact even caused by inappropriate or accidental movements.

Technical Specifications:

Machine Build Configuration:

Standard and Optional Accessories:

SCM Blade Off Brochure Link

Why Choose the SCM BLADE OFF System?

Reusability and quick back-to-operations: After the system is triggered, blades can return to work position in seconds. The blades do not get damaged, there are no cartridges to replace and, no re-calibration needed.

Quick start-up: The procedure of turning on and configuring the Blade Off system takes less than a minute. The operator will not even notice that and is not required to perform any start up activity.

It is a predictive system: The Blade Off system will prevent any contact with the main blade. No amputations, but also no minor injuries.

It is not assisted by a software or cameras: No cameras, algorithms, AI that determine a working space intrusion. More accurate and less false positives.

Protects from a wide variety of accident scenarios: Thanks to the responsiveness of the system, the operator is protected from high-speed accidents, which are generally caused by involuntary and sudden intrusion of the blade perimeter.

Works with any ambient lighting

Dust does not affect operability

Works also if the operator is wearing gloves

No proprietary tooling

15 HP main motor – unmatched

All the technology, quality, precision, and ease of use of a SCM slider

Differences Between the Class SI 400EP & L'invincibile SI 3 Blade Off: