ACMOS 100-5030, CALL FOR AVAILABILITY AND BEST LTL FREIGHT RATES

Acmos 100-5030, the all-in-one release agent for your edge bander spraying systems. Our unique water-based formula replaces multiple agents and eliminates the need for alcohol or silicone. Say goodbye to residue and cleaning headaches – our product delivers a proper release without any additional cleaning needed.

This release agent is intended for use on automatic feeders with edge-banding machines and spraying units to protect pressure rollers, conveyor belts, and wood and plastic surfaces. It can be poured into the appropriate storage tanks on the machine or applied with a brush or cloth.

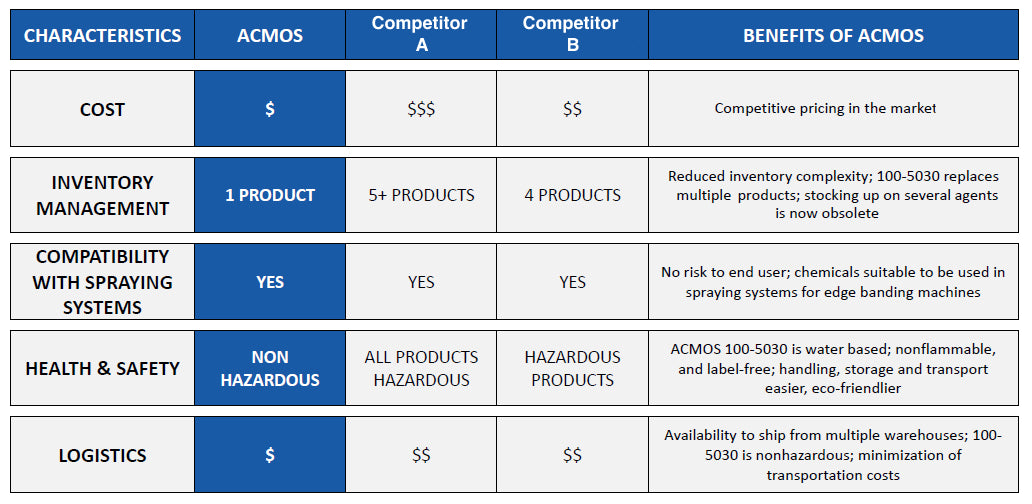

Acmos 100-5030 forms a thin, barely visible separating film that prevents hot-melt adhesive residues from sticking to surfaces of materials and equipment. It's also silicone-free and can be further diluted with water. Our non-flammable and non-hazardous formula is classified as non-Hazardous for shipping, making it more affordable to ship without any hazmat fees. Plus, it's safe to transport, handle, and store. Our product is listed in several manufacturer OEM manuals and warranties, so you can trust its effectiveness. Reduce inventory complexity and replace multiple products with Acmos 100-5030.

ACMOS 100-5030 Features

- Prevents adhesion of holt-melt adhesive residues on surfaces of materials and equipment

- Water based formulation; non-hazardous, non flammable

- Silicone-free, can be further diluted with water

- Protects pressure rollers, conveyor belts, and plastic surfaces against hot-melt adhesives

- Works well with EVA and PUR glues

- Does not affect finish on plywood, like competitor's products

Quick Summary

- Non-Hazardous Shipping

- Non-Flammable, Silicone-Free

- Water-Based Formulation

- Safer to Transport, Handle and Store

- Reduced Inventory Complexity, Replaces Several Products in One

- Listed in Several Manufacturer OEM Manuals and Warranties

Acmos 100-5030 Release Agent Brochure

Application: Automatic | Manual - It can be poured into the appropriate storage tanks on the machine or applied with a brush or cloth.

Recommended Uses: Automatic feeders with edge-banding machines and spraying units to protect pressure rollers, conveyor belts, and wood and plastic surfaces.

Non-Hazardous/Non-Hazmat for DOT Shipping

Available Container Sizes:

Liter/Kg: 1 (2 or 12 Pack Case) | 20 | 200

TECHNICAL DATA SHEET:

Range of applications:

Release agent, Coolant and Cleaning Agent for applicator rollers, Automatic and Manual

Properties:

Solution of active ingredients in water

Physical and chemical properties:

Form: Liquid

Appearance: Light Yellow

Smell: Characteristic

Density at 20°C: 1 g/ml ; DIN 51757

pH-value (500 g/l): 8,60

Active substances: 4,00

Viscosity at 20°C: < 59 sec ; Flow cup 4mm, DIN EN ISO 2431

Stockage:

Storage temperature: between 10°C and 30°C

Maximum storage: approx. 12 months

Processing:

Stir up before use. Do not store outdoors. Protect from heat and cold. Allow products to reach room temperature before use.

Why release agents are important

Release agents are critical to prevent glue and adhesives from sticking on both edgebanding machining tools and workpiece surfaces. They are developed in a liquid form and as such can be used in both automatic and manual edge processing.

Release agents are sprayed on the top and bottom of the workpiece edge areas. This prevents adhesive residue from sticking to the workpiece. Release Agents work with a variety of glues and adhesives for high-quality woods, veneers, and plastic-coated surfaces.

Advantages

Reduces production downtime due to cleaning. The process of edging can lead to unwanted glue residue on materials and equipment. Without the use of a release agent, glue residue can quickly stick and become very difficult to clean and remove. This results in a loss of production and machine downtime. Production employees are forced to spend valuable time cleaning up, instead of streamlining the manufacturing process. By using a release agent, a thin, barely visible lubricant film is formed, which prevents the adhesion of glue residues, thus avoiding time-consuming cleanup work.

Helps maintain production equipment. A common problem with edge processing is undesired glue buildup on machining tools. Glue buildup can cause unnecessary wear and tear on tools and lead to increased machine maintenance and costs. The continuous use of release agents protects the components of an edgebander, such as pressure rollers, trimming tools, hot melt adhesive tanks and buffing wheels against glue buildup. Using release agents is very important to the longevity of equipment.

Promotes high-quality finishes. Perfect, high-quality surfaces are a premium for edgebanding. During application, glue squeeze out occurs, which often creates glue lines and residue, thus affecting the quality of finished products. Release agents used during the edgebanding process prevent adhesive residues from sticking, while protecting the edge and foil from marks and friction, thus providing excellent surfaces.