Innovative high-performance single blade beam saws in quality for cut finishing and working speed in order to meet the production needs of the furniture companies. It is the ideal solution for companies requiring to process small to medium batches. Gabbiani G3 offers processing solutions to satisfy every single customer demand.

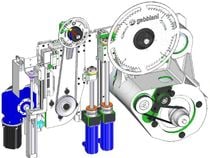

HI-TRONIC DEVICE: high technology on the saw carriage.

Very high quality finishing cutting standards together with high speed and precision with the total electronic control of the blades.

FLEXCUT 1/D: more cuts in less time.

High efficiency due to the use of 2 pushers with a completely independent stroke.

Drastic reduction in machining cycle times due to the simultaneous processing of several bars with different cuts.

Extreme flexibility is achieved as the mobile unit is fitted with two grippers, the second one can be excluded, therefore guaranteeing a wide variability in the width of the strips that can be gripped.

PRISMATIC GUIDES WITH RECIRCULATING SPHERES: maximum linearity and minimum friction.

Increased productivity capacity both with high speed, that can be reached during the feeding stroke and a return stroke (up to 170 m/min).

The centralised lubrication, verified by control, guarantees the complete lack of maintenance.

PUSHER BEAM: maximum linearity and long time precision.

Fast cycle times with high speeds in the return stroke (up to 135 m/min).

Centralised and automated lubrication system that is managed by the PC (video monitoring) ensures the lack of maintenance.

| gabbiani g 3 130 | gabbiani g 3 145 | gabbiani g 3 165 | |||

| Cutting lenght | mm | 3200/3800/4500 | |||

| Blade projection | mm | 130 | 145 | 165 | |

| Main blade motor power (option) | kW | 15 (18 - 22 - 30 -37) | 18,5 (22 - 30 - 37) | ||

| Rotating speed – 50 Hz | r.p.m. | 3500 | 2950 | ||

| Saw carriage variable speed (option) | m/min | 0 - 170 | |||

| Pusher variable speed | m/min | 135 | |||

| Kit for plastic materials cutting | Available | ||||

| HI-TRONIC device | Available | Std. | |||

| FLEXCUT device | 1/D | - | |||

| Number of clamps | std |

6 (3 of which with double finger on the squaring area) |

|||