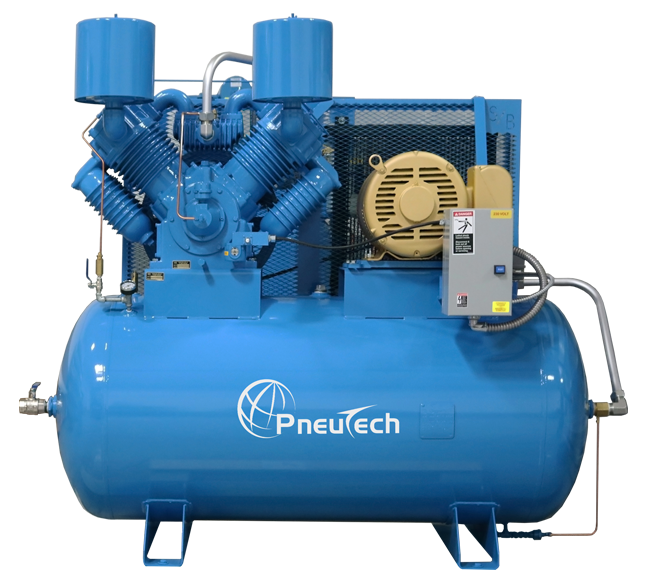

PSB Piston compressors are incredibly reliable units that range from 5-30 HP. They are built to last in manufacturing environments that require smaller amounts of HP at a constant load.

Brochure for PSB Piston-Style Air Compressors 5-30 HP

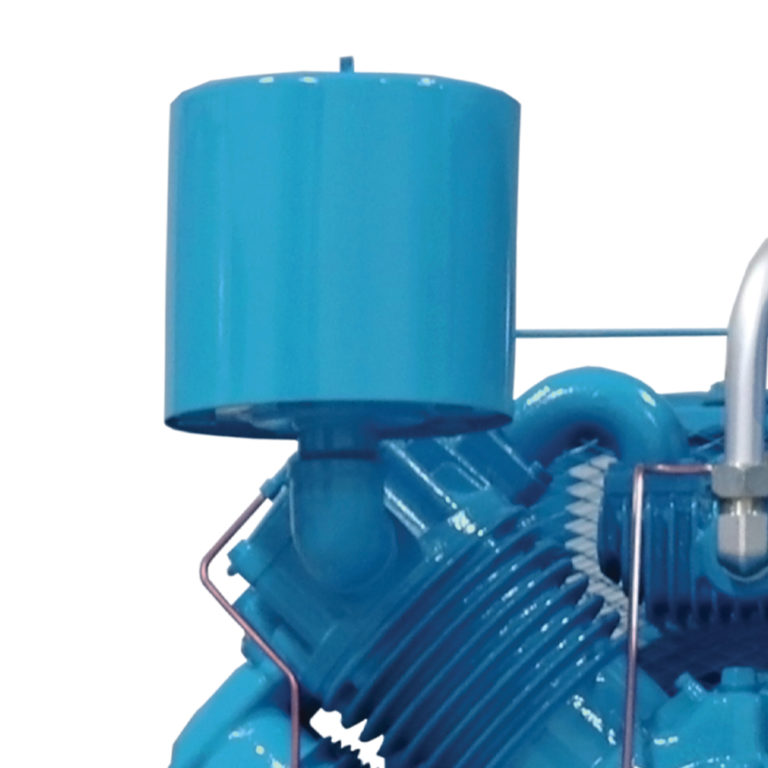

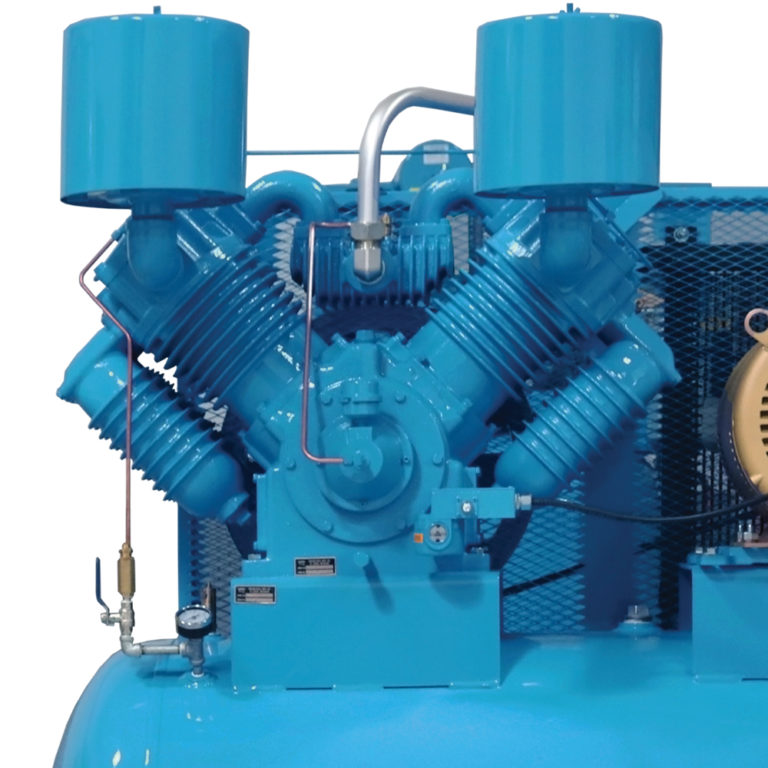

Silencing Type Air Filter – Increases the lifespan of the pump and reduces noise level.

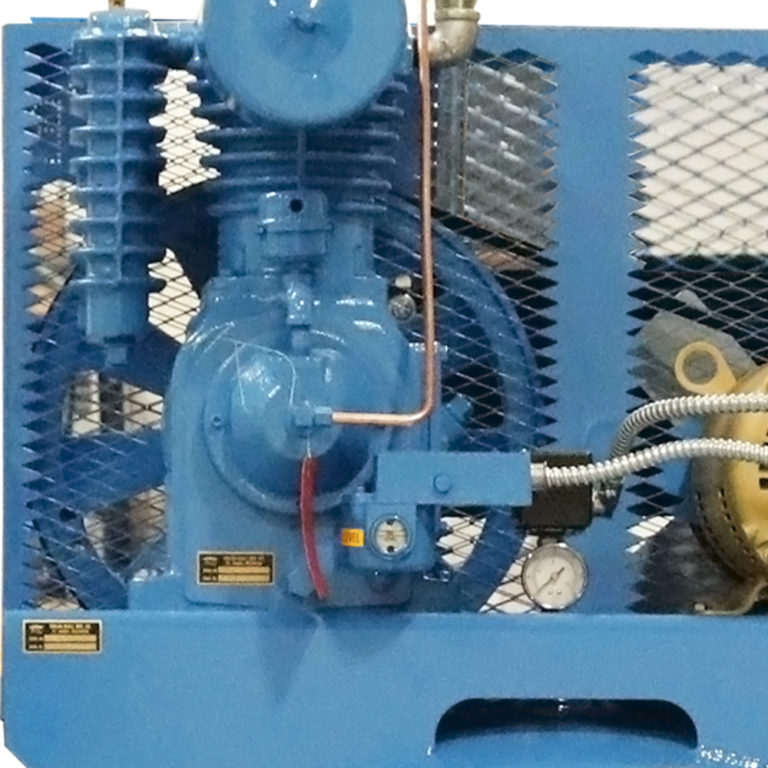

Automatic Drain Valve – Automatically drains moisture from the tank to prevent corrosion and reduce moisture in the compressed air.

Centrifugal Unloader – The centrifugal unloader makes sure that the pump starts with no head pressure. Increases the life of the electric motor.

Low Oil Shutdown – This switch shuts down the compressor if low oil is detected, saving the compressor from catastrophic failure.

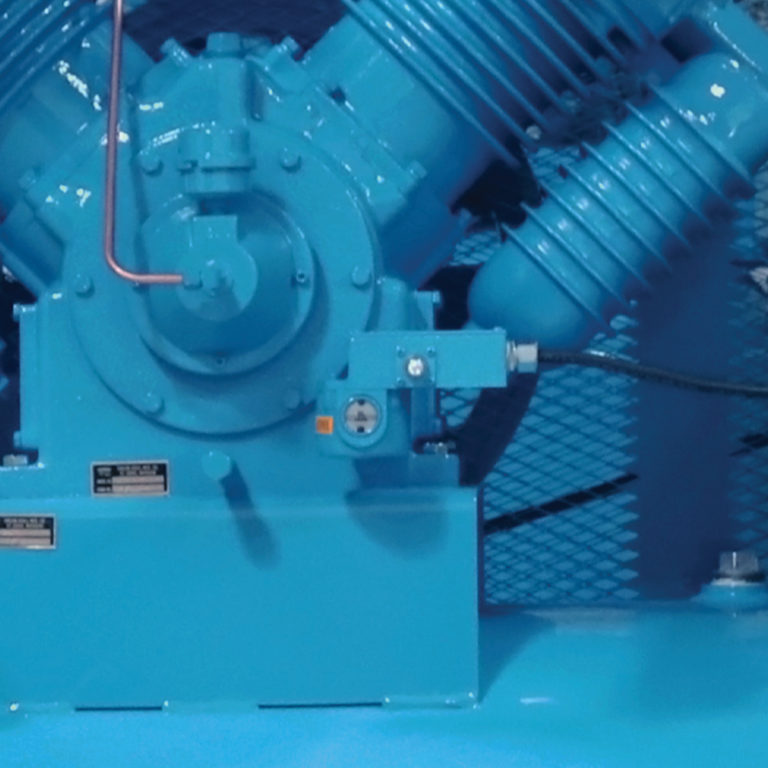

Iron Crankshaft & Pump – The ductile iron crankshaft provides extra strength, delivers longer wear and has a large diameter. The pump is 100% cast iron, extremely durable, and made in the USA.

Air-Cooled Aftercooler – Brings hot compressed air to within 15°F of ambient temperature. The cool air then condenses moisture in the tank and is drained automatically.

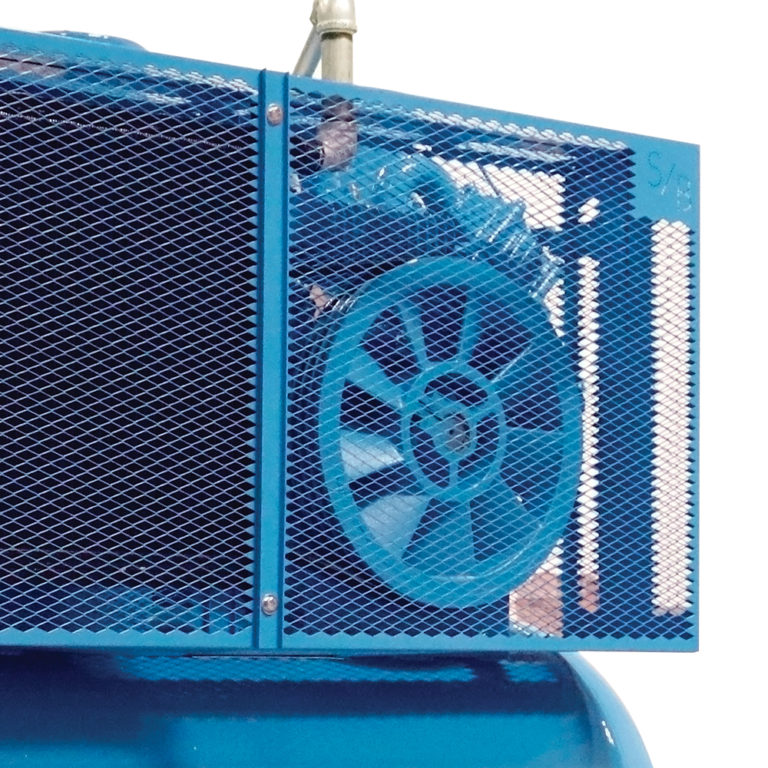

Low RPM – The extremely quiet unit has a large diameter and low RPMs, leading to a long lifespan due.

Large Receiver Tank (ASME Certified) – The large air receiver tank allows for fewer starts and stops. A certified safety valve and pressure gauge are included.

High Efficiency Motor – PSB piston compressors feature the Baldor “Super E” series motor offering a very high efficiency and long life.

Dual Control – Allows the compressor to run constantly by loading and unloading during periods of high demand, or in standard start-stop mode. This can greatly reduce heat build-up in the motor caused by excessive starts and stops.