RDA Non-Cycling dryers are an excellent way to keep moisture out of your compressed air system with a relatively low initial investment.

Brochure for RDA Non-Cycling Dryers 13-550 CFM

Performance – RDA dryers achieve excellent performance even in instances of high ambient (122°F) and high inlet temperatures (158°F), maintaining a low humidity.

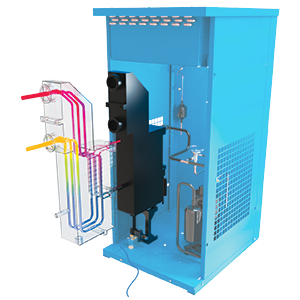

Vertical Heat Exchanger Design – The patented aluminum heat exchanger has been designed to offer the maximum performance and minimum pressure drop. The unique heat exchanger is both an air to air heat exchanger as well as an air to refrigeration heat exchanger. The warm and humid air is pre-cooled by the cool dry air that is leaving the dryer, which increases efficiency.

Electronic Control – All models have an electronic control board, with a double sensor system that keeps the dew point and condensing pressure within ideal operating parameters.

Condenser Fan | Coils – Generous sizing of the condenser unit ensures maximum performance of the refrigerant circuit and the ability to operate with changes in ambient conditions quickly. Access to the condenser for cleaning and maintenance is simple.

Serviceability – With an average Phillips screwdriver, the panel protecting the major components of the refrigerated dryer slides off, meaning that servicing is not complex and less costly.

Single Point Condensate Drain – All RDA models come with a single point condensate connection.

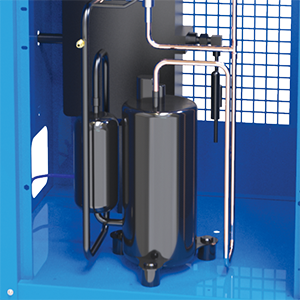

Refrigeration Compressor – The circulation of the refrigerant in the cooling system is done through the highly efficient refrigerant compressor. Thanks to its innovative construction, this has reduced energy consumption and increased reliability levels.

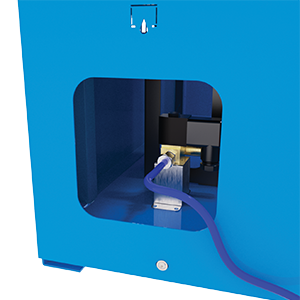

Condensate Drain Controls – RDA dryers are equipped with an electronic drain valve which is controlled by the programmable controller. Not only does the controller ensure timely draining of the condensation, but also allows for easy programming and testing of the drain valve.