Integrated Moisture Separator – Integrated moisture separator comes standard for all Ri units. Up to 90% reduction in condensation when compared to a unit without a moisture separator. Compatible with optional energy recovery.

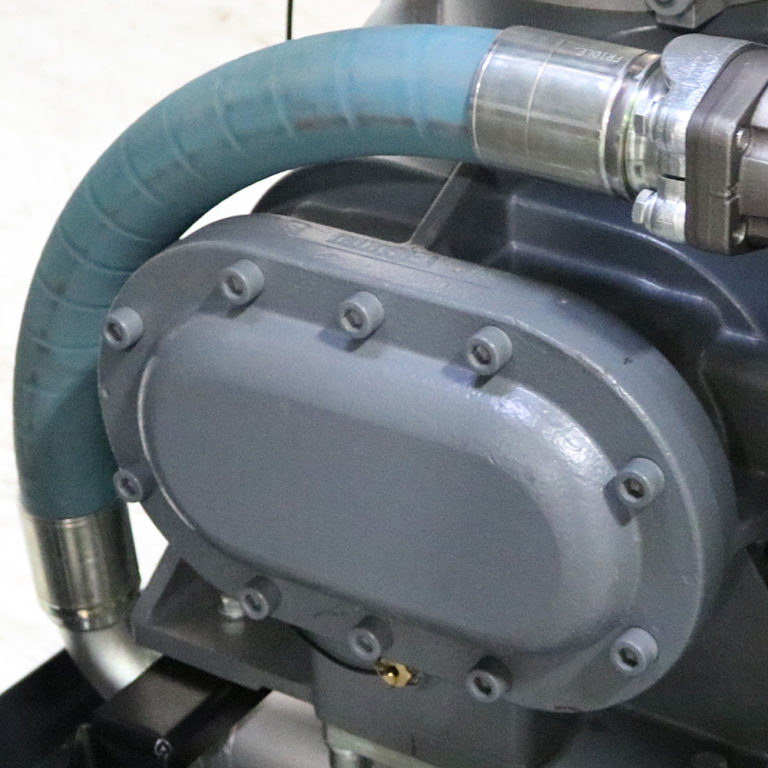

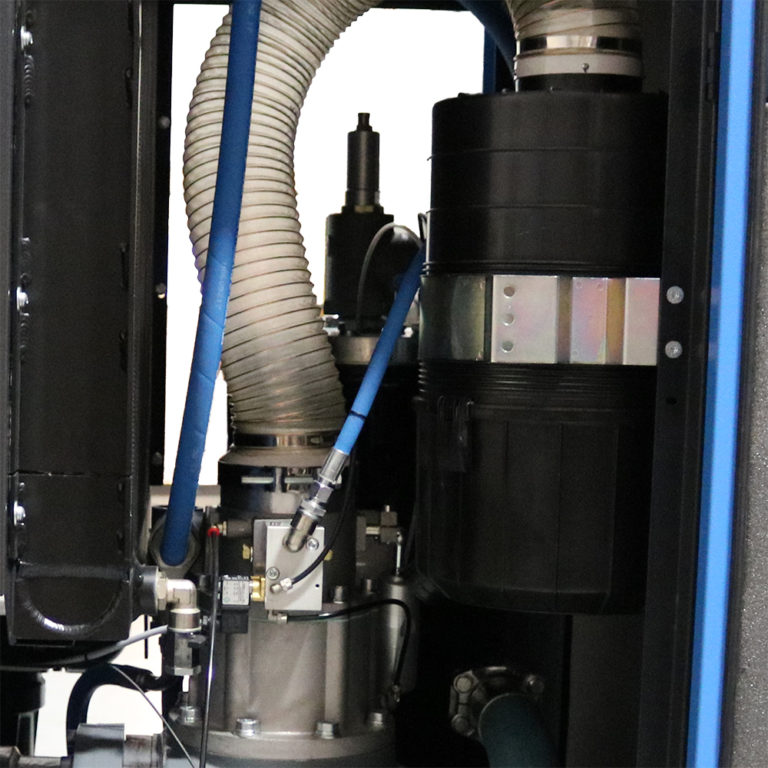

Single Screw Airend – The rotary screw on this unit comes standard with oversized, low RPM airends that are designed for maximum efficiency and excellent reliability.

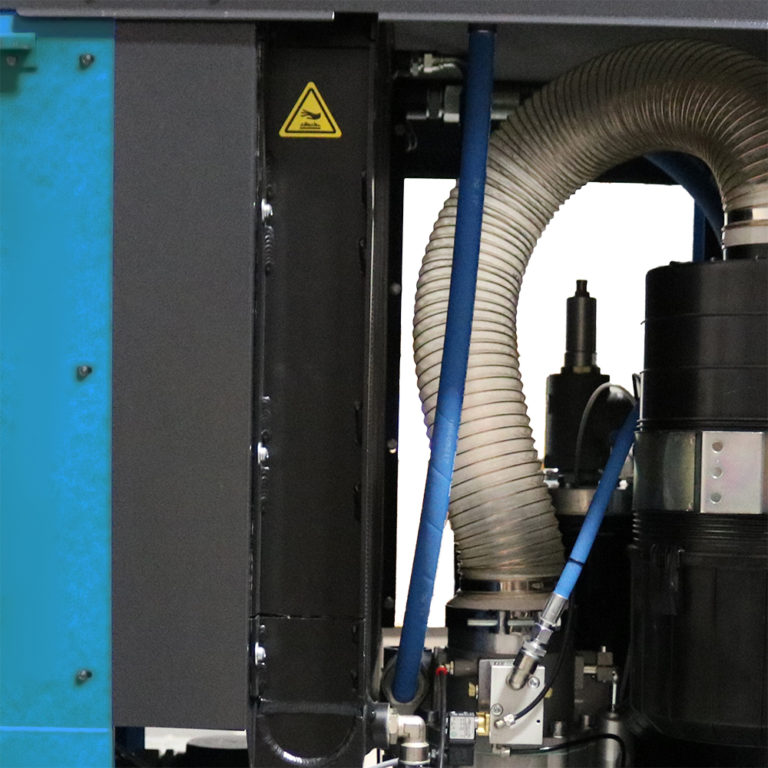

Low Speed Centrifugal Fan – Dedicated low-speed centrifugal fans for both the oil and the air coolers. Separate fans maintain optimal temperatures for the oil and air while yielding extremely low noise levels.

Air/Oil Cooler – The cooler is oversized in order to ensure optimum working temperatures in any environmental condition. Conveniently placed so that they are easy to clean.

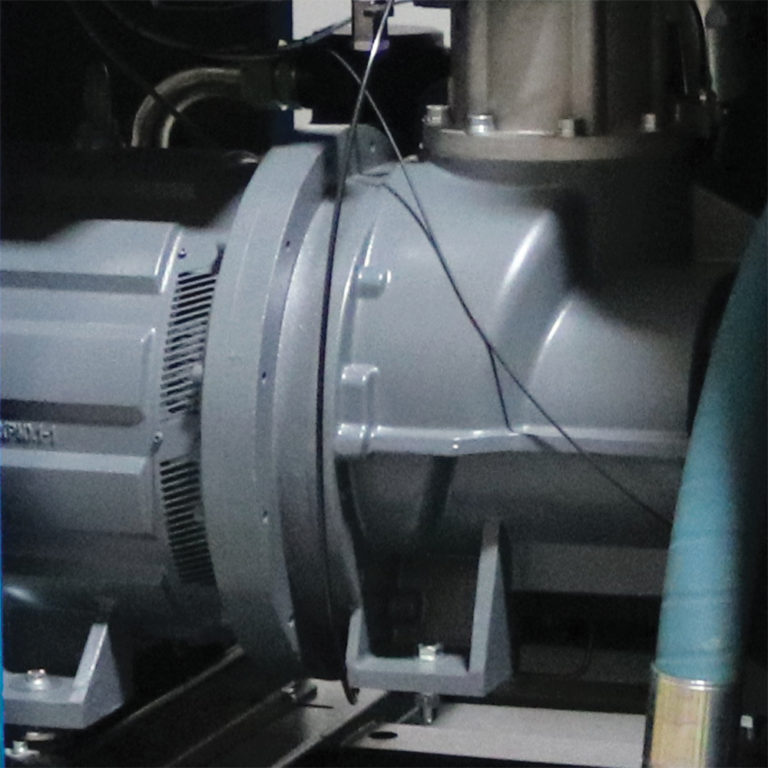

Permanent Magnet Motor – Synchronous motors with permanent magnets and frequency converters do not have any bearings, flexible couplings, or sealing gaskets. Eliminates wear, leakage and replacement.

Electronic Controller – Controls the main operating parameters and daily or weekly start program with CAN-BAS interface. Connects up to four compressors in a network, duty cycle monitoring, and maintenance timers.

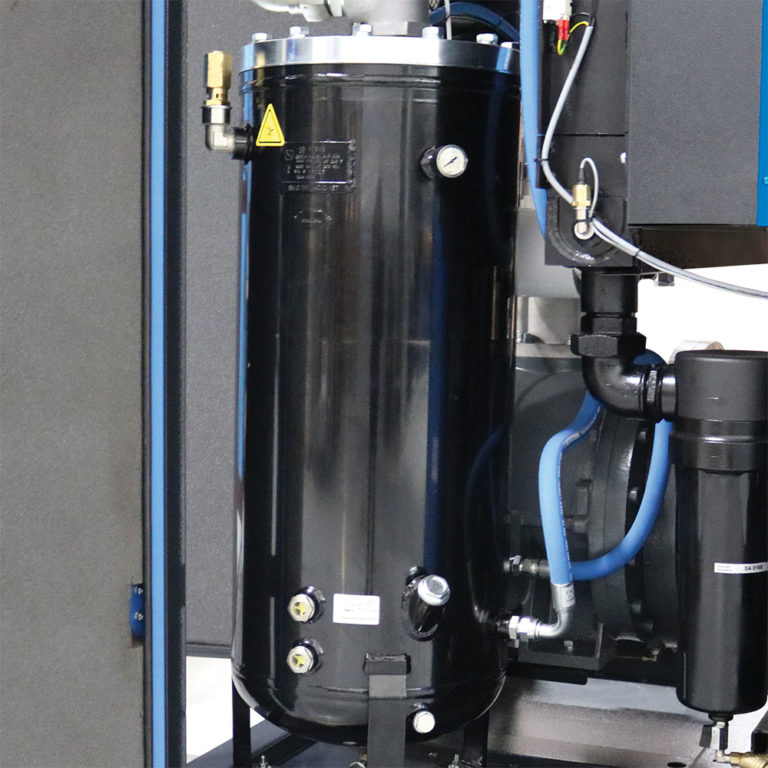

Air/Oil Separator Tank – The exclusive cyclone technology guarantees a pre-separation efficiency of more than 99.9%. The separator ensures low oil carryover of less than 2 ppm which reduces maintenance.

Intake Filter – Removes the smallest particles of dust and dirt. The large surface area ensures a long life and minimal pressure loss. Conveniently located near the removable panel for easy access.