The SCM Class S 630 is a robust, heavy-duty 24” planer engineered for high-performance woodworking applications. Built on a sturdy monoblock base, this machine ensures stability and precision while handling even the most demanding workloads. Featuring the advanced XYLENT helical insert cutterhead, it delivers an exceptionally smooth finish with reduced noise levels, enhancing both efficiency and operator comfort. Equipped with an electric-powered feed table adjustment, variable feed speeds, and a steel sectioned infeed with rubber outfeed rollers, the S 630 offers superior material control and consistency. Additional highlights include an electronic LED readout for precise thickness settings, a durable dust hood, and a powerful 14 HP motor, making it a top choice for professionals who require accuracy, durability, and performance in their workshop.

STANDARD EQUIPMENT

- Spiral, shear cut, XYLENT helical insert cutterhead

- Electric powered movement feed table raise and lower (2 speed)

- Steel, sectioned infeed

- Two rubber outfeed rollers

- Variable feed system

- Powered bearing-assisted feed rollers

- Digital LED readout of working thickness

- Magnetic starter with overload protection

- Table lifting by four high precision jack screws

- Adjustable bed rollers in feed table

- Course and fine thickness adjustment

- 10 additional knives

- Dust hood

The Best Finish and Feeding Effectiveness of any material and in any working condition thanks to the pneumatic adjustment of rollers that allows to change at any time the pressure exerted on the work piece.

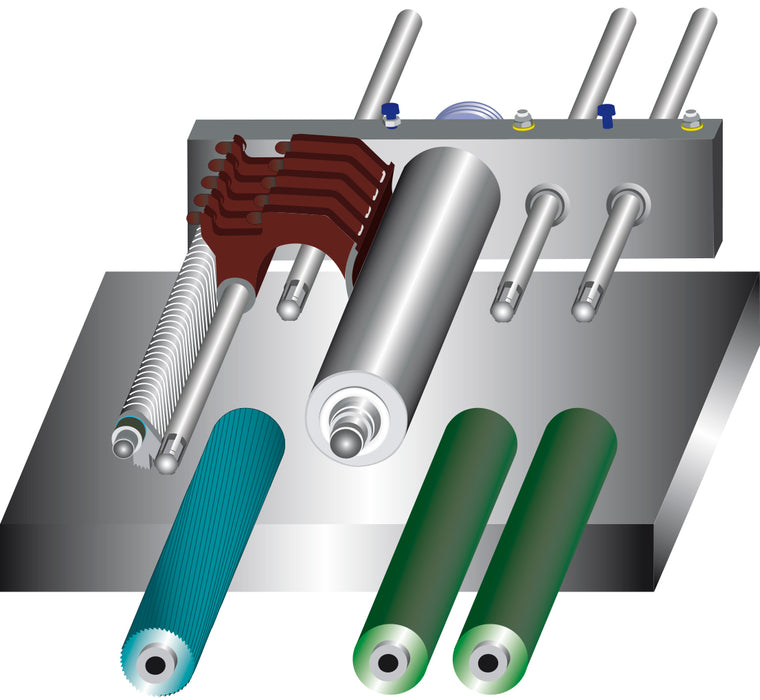

One Machine for Every Requirement with the Interchangeable Rollers. Quick and easy changeover of the rollers that allows the operator to configure the machine drive function in case of special requirements such as minimum removal of fine wood and/or batches where multiple pieces of different thicknesses are processed.

Perfect Finish with the Feeding Rollers on Connecting Rods. The stopping of the work piece and the presence of notches on its surface are eliminated due to the movement system on all three rollers that allows their vertical displacement by rotation and the best linear feeding.

Sturdy Structure with Precision when Moving the Worktable

The 4 screws with a large diameter combined with the 2 side linear guides ensure worktable stability eliminating the necessity of locking in position. The integrated protections guarantee high precision and reliability over time.

Exceptional Finish with the “Xylent” Spiral Knife (3 spiral knives)

Reduced noise during machining provides a more comfortable working environment. It also improves the dust extraction due to the production of very small chips. Each cutter has 4 tips which can be rotated into the cutting position when worn. Therefore increasing the production life of the cutter block before knives require replacement.

Monoblock Base

Monoblock technology is used in the design and fabrication of this base. The solid, welded base undergoes a treatment call normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

Powered Table Lifting System

All SCM planers use four jack screws with acme style threads and dust covers for maximum table support. In addition to providing a stable lifting system which eliminates sniping, the acme threads greatly increase the longevity of what is normally the most common wear item on planers. Through a patented design, there is a special bushing between the drive chain,

and sprocket which doesn’t allow any pressure from the chain to reach the jack screw, thus pushing the machine’s longevity to the extreme. It is equipped with a powered raise and lower system with an LED readout for accurate positioning.

Work Table Support Rollers

Used when planing raw, uneven lumber, this feature allows irregular material to be planed that would not feed on a standard table. When the material has been planned flat on one side, the rollers can be lowered to allow a clean pass on the other side.

Planer Head Assembly

The SCM feed system includes a powered sectional steel infeed roller and powered rubber outfeed rollers. This combination helps ensure feeding of parts with variations up to 6mm in thickness. Anti-kickback fingers and a sectional chip breaker are also part of the feed section and provide both safety and a quality finish.

Electronic Led Readout

The Class S 630 has an ergonomically positioned controller which gives an electronic readout of the planer thickness. Also featured as standard is a variable feed speed control.

XYLENT Spiral Cutterhead

This amazing SCM Group Jointer now comes with the most innovative solution for soundless planing in the world. The 24” cutterhead version comes with a spiral knife cutterblock with 3 series of knives. Totaling 105 plates of 15x15x2.5mm. These are four self-locking and self-centering screw knives. With each cutterhead you will also receive 1 dynamometric key for the correct and safe use of the locking mechanism (think of a mini torque wrench). Additionally, you will receive two inserts for the dynamometric key.

MACHINE CONFIGURATION

**Specifications are subject to change**